“CHOP YOUR OWN WOOD AND IT WILL WARM YOU TWICE.” – HENRY FORD

CUT YOUR OWN WITH A CHAINSAW TO BEGIN WITH, AND THAT’S ONE MORE.

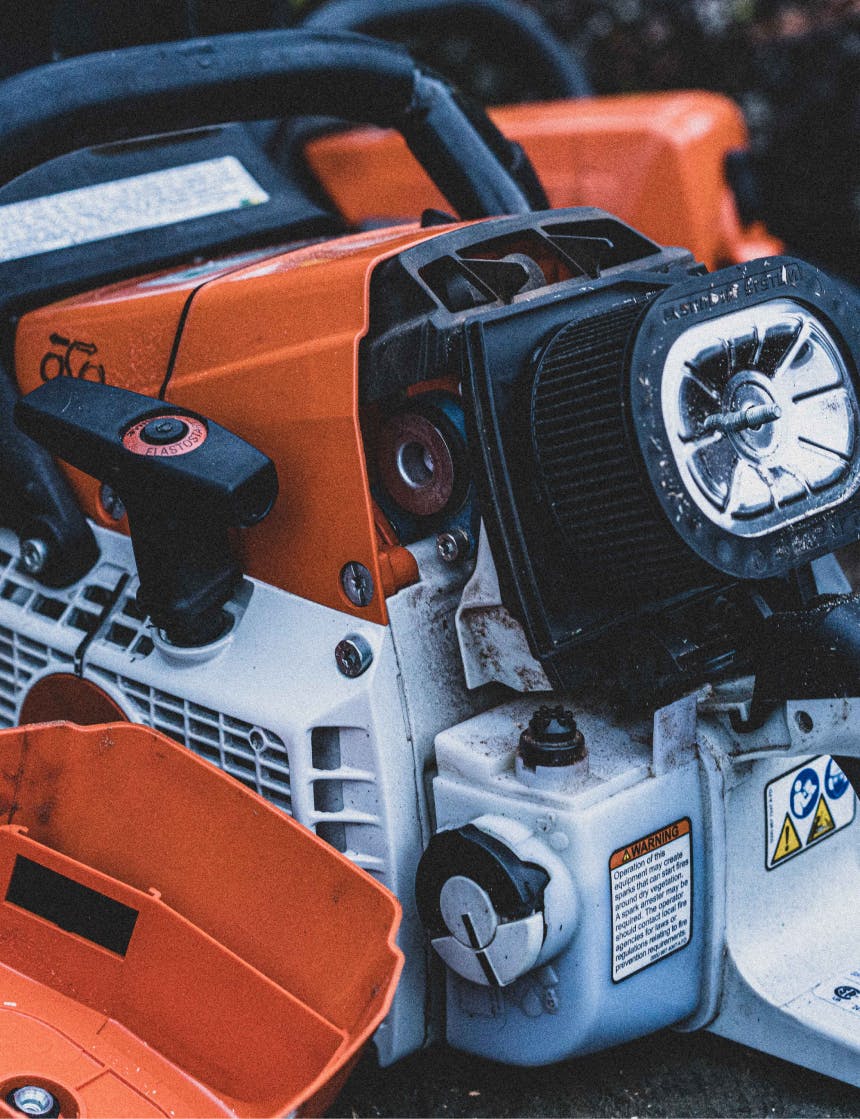

Whether felling, bucking and limbing, or cutting up logs for firewood, it doesn’t take long to burn through a tank of fuel when running a saw at full throttle. A finely tuned, sharp saw is a pleasure to own and a life-long tool — only if properly maintained. Every re-fuel and oil is the perfect time to do a quick once-over to make sure your saw is in top running condition. Anyone who’s put their time into a chainsaw knows a sharp, well-oiled and finely tuned machine is an absolute must for reducing the time it takes to get the job done. These are the basics.

THE KIT

What to have on hand: Fuel, 2-cycle oil, bar and chain oil, rags, cleaning brushes, appropriate size round file and guide, spare files, depth gauge and flat file, combination socket tool, small flathead screwdriver, spare spark plug, and ear and eye protection. The combination tool usually comes with the saw and is used for tensioning the chain and removing the bar and spark

FUELING UP

There’s a wide range of choices in fuel, 2-cycle oil and bar oil for a chainsaw. As with anything you buy, choosing the highest quality always pays off in the end. Most saw makers suggest a high-octane, ethanol-free premium fuel for best performance and engine protection. Running pure fuel “E free” will reduce wear and tear on plastic and rubber parts and protect against water accumulation in the fuel tank. Always make sure you’re using a properly mixed fuel-to-oil ratio using only a high-quality 2-cycle engine oil. Store fuel in metal containers to maintain stability.

A high-quality bar oil should be thick and stringy, and operable in extreme temperatures. One test of the bar oil is to quickly remove the bar oil cap and look for long strings of oil between the saw and cap or between fingers.

Before removing, wipe around the filler caps to remove any debris that might fall into the tank. Then fill, being careful to not overfill either the bar oil or fuel tanks, which can cause an unwanted vacuum in the fuel system and wasteful spillage.

SHARPENING

Perhaps nothing is as important as a sharp chain when running a saw. Whether carrying a spare sharp chain to swap out or hand sharpening throughout the day in the field, a sharp chain makes the job easier on you and your saw. A sharp saw is also a safe saw, allowing ease of cutting and reduction of potential kick-back when run at a high rpm. Regularly hand sharpening the chain teeth with a file and guide not only keeps the teeth sharp but gives you a chance to inspect each tooth for any cracks, nicks or rock dings. Not all chains are the same size and pitch. Know the file size and angle of your chain as per manufacture. Likewise, not all files are made equal. For a high-quality and long-lasting file, look for German and Swiss brand name files.

Apply the chain brake. Begin by marking the first tooth to be filed. Sharpen each tooth with long, steady strokes of the file, paying careful attention to the correct angle. Rotate the file inside the guide occasionally for fresh cutting teeth and even file wear. Sharpen each tooth to the same length. Consistency in each tooth is key. Next, begin again at the first tooth, and, using the depth gauge and flat file, file down each raker per the depth gauge. If the chain or any one tooth is severely damaged, replace it with a new chain so you can keep working, and fix the damaged one back at the bench.

Cleaning

Whether it’s the big fir, pine and tamarack of the north country or slow-growing hardwoods, each cut of the saw creates an aromatic mound of fresh wood chips and fine, powdery sawdust. While any woodsman would consider this build-up as a benefit of the job, it can bog down the saw, restrict bar oil dispersion, and create unwanted accumulation on critical components.

Unscrew the nuts on the chain cover and place them on a rag. Remove cover, bar and chain. Using a soft, dry paint brush or rag, remove all debris from the powerhead, cover and bar. Pay careful attention to the oiling holes on the powerhead and on the bar. If cutting sappy, pitchy wood, use a little fuel, soap or light degreaser on a damp rag to help cut the pitch.

Run your socket tool down the groove in the bar where the chain rides to remove any build-up of debris. Both the socket tool and the pointed end of the depth gauge are made for this task. This is a good time to check around the entire bar groove for any burrs on the flat side of the bar. Carefully remove any metal burrs with a flat file. Flip the bar each time you assemble the bar and chain for even bar wear. (This is why you see saws with the brand name on the bar upside down.)

Check the air filter and gently brush off any build-up with a soft rag or brush. When cleaning the air filter, put the thumb lever in the choke position to prevent any debris from going in the carburetor. Wipe clean the inside of the air cleaner cover. Wipe the inside of the cover with a very small amount of oil to catch extra dust before it even hits the filter.

Reassemble the saw and repeat these simple steps each time you refuel, and get back to cutting.